Planning

Having real-time insight into your available resources (manpower, machinery and materials) results in a more flexible process. Lines can be used more effectively, bottlenecks become visible instantly and it is possible to make changes on the fly. Planning with predefined tried-and-true recipes prevents errors. Visual Link Software's Planning functionality translates the overall order into a detailed production planning, down to the hour and minute level. Besides the current order, all other orders are taken into account as well and the module supports the planning process to achieve the most efficient production method. Planning extracts all the information it needs from Definition and Resources.

Release

Once the planner finishes their work, it has been verified that all required resources are available and that the product in its entirety is known, it is time to begin the production process. For each production run, Release tracks exactly how and what parameters were defined for that specific run. This includes e.g. the work instructions, the production lines that are used and any other additions. Every subsequent order that has to meet the same requirements will be produced using this blueprint. The Release functionality adds an additional safeguard; once all parameters have been verified and approved, the green light is given to take the order to the production floor.

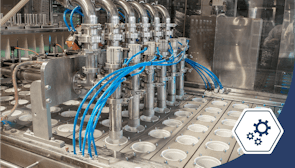

Execution

Execution sends the data live to the machine pool and communicates with the operators via the tablets. It is Execution's responsibility to ensure that the production process actually begins. It directs the PLCs, feeds the correct data to the visualisation software (SCADA) and ensures everything proceeds smoothly. During the execution of the production process, a vast amount of data is being generated. How fast is each line running, what is the loss rate, where do problems keep occurring and how long is a line shut down? We recommend implementing the Data Collection functionality alongside Analysis (including OEE) and Track & Trace. Analysing these data will provide insight into bottlenecks that are often easily resolved.